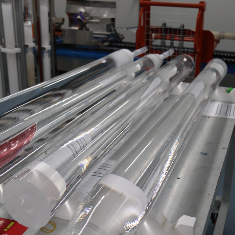

130mm fiber preform rod is manufactured by the combined production process of VAD mandrel and OVD cladding. The main component is SiO2, which is doped with other components such as F and Ge in a specific area according to the product characteristics. The outer diameter of the finished preform rod is about 130mm. It is used to fabricate single-mode optical fibers meeting ITU-T G.652.B/D and ITU-T G.657.A1/A2/B3 standards.

The product application

According to customers' requirements, we can manufacture a variety of G.652, G.657 single mode fiber.

Product standards

Key technical performance is better than ITU-T and related national standards.

Product features

Stable refractive index profile, accurate geometry, very low loss characteristics.

Geometric performance

Outer diameter of preform (O.D.) 130-150 (±5) [mm]

Tolerance of O.D. (Tolerance of O.D.) ≤5 [mm]

Effective length of preform (Effective L.) ≥1600 [mm]

The effective weight of preform (Effective W.) ≥45 [Kg]

Non-cirlucarity of preform ≤1%

Concentricity error of core/cladding ≤0.5 [mm]

Bow degree (Bow) ≤1.0 [mm/m]

Appearance defect performance

Mandrel area without defects

The number of bubbles allowed to exist in the cladding area of the preform per meter L is the diameter of the bubbles

L≤0.5 mm-

0.5 mm≤L≤1.0 mm ≤8

1.0 mm≤L≤2.0 mm ≤4

L>2.0 mm 0

The core/cladding interface has no obvious contaminants, impurities, cracks, scratches, etc. (white impurities, spiral gas lines, etc. have no effect on wire drawing)

The surface of the preform is smooth, without scars, and without damage

Main technical performance of drawn optical fiber products (conventional G.652.D)

1310nm attenuation ≤0.344 [dB/km]

1383nm attenuation ≤0.344 [dB/km]

1550nm attenuation ≤0.204 [dB/km]

1625nm attenuation ≤0.244 [dB/km]

Dispersion in the wavelength range of 1285-1339nm ≤3.5 [ps/(nm·km)]

Dispersion in the wavelength range of 1271-1360nm ≤5.3 [ps/(nm·km)]

1550nm dispersion ≤18.4 [ps/(nm·km)]

1625nm dispersion ≤22.4 [ps/(nm·km)]

Zero dispersion wavelength 1312±12.4 [nm]

Zero dispersion slope ≤0.092 [ps/(nm2·km)]

Fiber cut-off wavelength λc 1150-1337 [nm]

1310nm Mode Field Diameter (MFD) 9.2±0.44 [μm]

1550nm Mode Field Diameter (MFD) 10.4±0.8 [μm]

Attenuation discontinuity 1310nm, 1550nm ≤0.05 [dB]

Core/cladding concentricity error ≤0.54 [μm]

Out-of-roundness of cladding ≤1.04 [%]